Materials

-

High Performance > 300°F

- Polyetheretherketone (PEEK)

- Polyphenylene Sulfide (PPS)

- Polyetherimide (Ultem®)

- Sulfones

-

Engineering 185°F - 300°F

- Acetal

- Nylon

- Polyesters

- Polycarbonate

- Polyphenylene Oxide (PPO)

- Polyvinylidene Fluoride (PVDF)

-

General Industrial < 185°F

- Polypropylene

- Polyethylene

- Acrylonitrile Butadiene Styrene

Certification

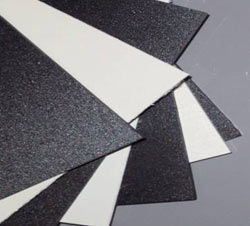

DELRIN® acetal homopolymer

Delrin® sheets are also available in an array of standard stock colors in addition to Natural and Black, requiring no minimum production size or additional lead time.

Learn more: Delrin® Sheet in Standard Colors

Ensinger's Delrin® 150 stock shapes are a homopolymer acetal manufactured using DuPont Delrin 150 Resin. It is a crystalline plastic which offers an excellent balance of properties to bridge the gap between metals and plastics. It possesses high tensile and flexural properties, along with creep resistance and toughness, while exhibiting low moisture absorption, and fatigue endurance.

| Properties | Metric | English | Comments | |

|---|---|---|---|---|

| Physical | Specific Gravity | 1.42 g/cc | 1.42 g/cc | ASTM D792 |

| Water Absorption | 0.250 % @Time 24.0 hour |

0.250 % @Time 24.0 hour |

ASTM D570 | |

| Water Absorption at Saturation | 0.900 % | 0.900 % | ASTM D570 | |

| Mechanical | Hardness, Rockwell M | 94.0 | 94.0 | ASTM D785 |

| Hardness, Rockwell R | 120 | 120 | ASTM D785 | |

| Tensile Strength, Yield | 75.8 MPa | 11000 psi | ASTM D638 | |

| Elongation at Break | 25.0 % | 25.0 % | ASTM D638 | |

| Tensile Modulus | 3.10 GPa | 450 ksi | ASTM D638 | |

| Flexural Modulus | 2.90 GPa | 420 ksi | ASTM D790 | |

| Flexural Strength | 110 MPa | 16000 psi | ASTM D790 | |

| Compressive Strength | 35.9 MPa | 5200 psi | ASTM D695 | |

| Izod Impact, Unnotched | 0.80 J/cm | 1.5 ft-lb/in | ASTM D256 | |

| Coefficient of Friction, Dynamic | 0.200 | 0.200 | 40 psi, 50 fpm; ASTM D3702 | |

| K (wear) Factor | 111 x 10-8 mm/N-M | 55.0 x 10-10 in-min/ft-lb-hr | ASTM D3702 | |

| Limiting Pressure Velocity | 0.0513 MPa-m/sec | 1460 psi-ft/min | ASTM D792 | |

| Electrical | Volume Resistivity | 1.00e+15 ohm-cm | 1.00e+15 ohm-cm | ASTM D257 |

| Dielectric Constant | 3.70 @Frequency 60.0 Hz |

3.70 @Frequency 60.0 Hz |

50% RH; ASTM D150 | |

| Dielectric Strength | 19.7 kV/mm | 500 kV/in | ASTM D149 | |

| Dissipation Factor | 0.00500 @Frequency 60.0 Hz |

0.00500 @Frequency 60.0 Hz |

ASTM D150 | |

| Thermal | CTE, linear | 122 µ m/m-°C | 68.0 µ in/in-°F | ASTM D696 |

| Melting Point | 175 °C | 347 °F | ASTM D2133 | |

| Maximum Service Temperature, Air | 85.0 °C | 185 °F | Continuous; UL746B | |

| 149°C | 300°F | Intermittent | ||

| Deflection Temperature at 0.46 MPa (66 psi) | 169 °C | 336 °F | ASTM D648 | |

| Deflection Temperature at 1.8 MPa (264 psi) | 125 °C | 257 °F | ASTM D648 | |

| Flammability, UL94 | HB | HB | UL 94 |

Website

Website